Project Details

The Site

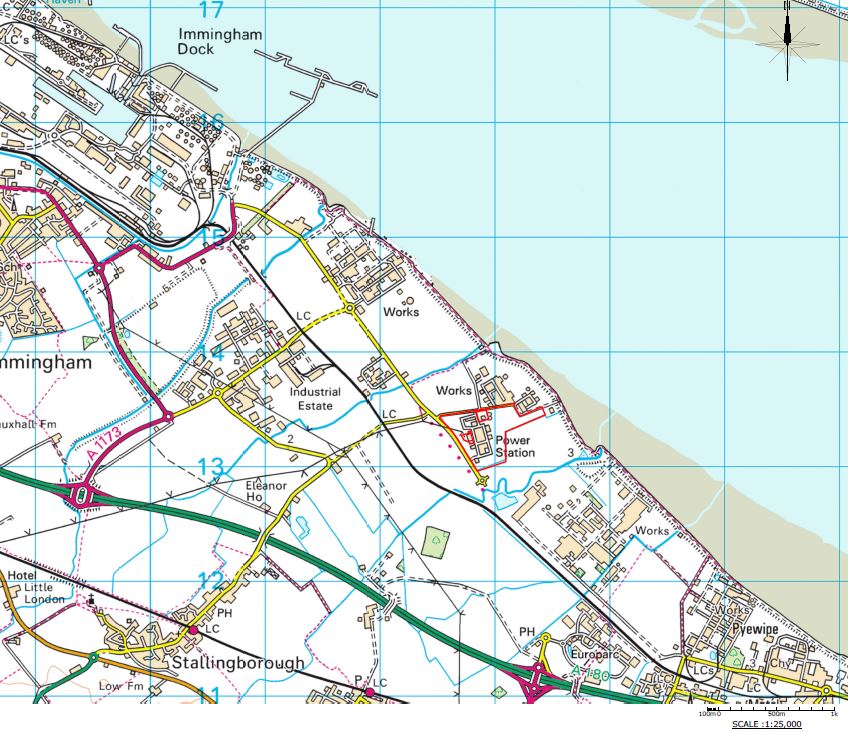

SHBEC will be built on available land within and adjoining the SHBPS site on South Marsh Road, near Stallingborough, between Immingham and Grimsby, in North East Lincolnshire.

The Main Development Area for SHBEC (the part of the Site that the EfW power will be built upon) is located to the east of the existing CCGT power station and comprises largely undeveloped land. Cooling water pipelines (associated with the CCGT power station) and other utilities cross the Main Development Area below ground and these have influenced the layout of the EfW power station.

The remainder of the Site (outside the Main Development Area) comprises the operational SHBPS site and a section of South Marsh Road. Some of the land within SHBPS will be used in connection with SHBEC for temporary construction laydown purposes, along with utilities connections, ecological mitigation, and access.

A plan showing the Proposed Development Site Order Limits compared to the April 2019 Planning Permission boundary is submitted for the Development Consent Order application as Document 4.12.

The Site is located within an area that comprises a mix of industrial and agricultural land use with the Humber Estuary to the east. The nearest residential properties are located approximately 1 kilometre west of the Site on South Marsh Road. The nearest settlement is the village of Stallingborough over 2 kilometres to the south-west.

The Site is accessed from both the west, along Hobson Way, and from the north, along South Marsh Road and has good access to the A180, which avoids traffic having to pass through residential areas.

The EfW Power Station

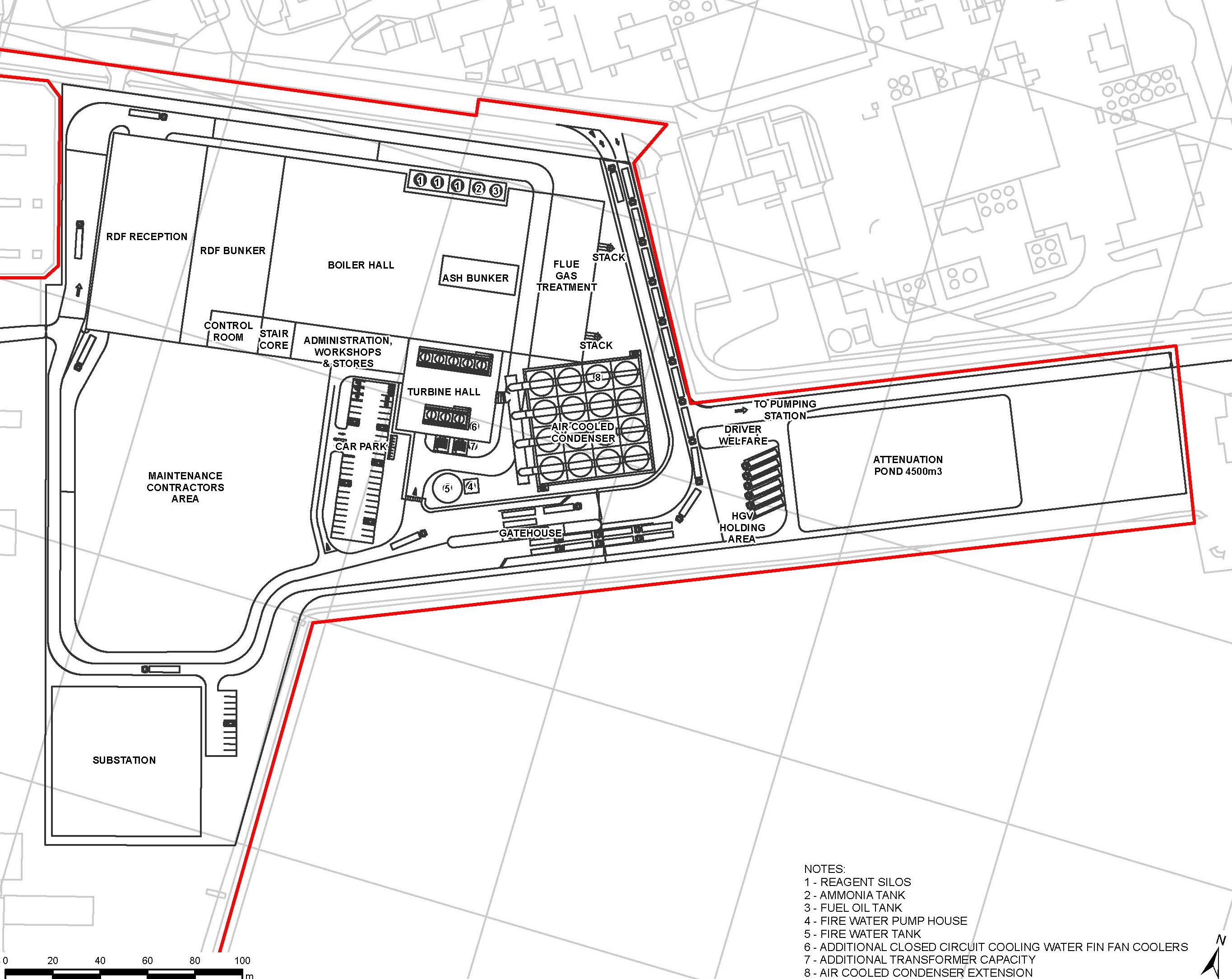

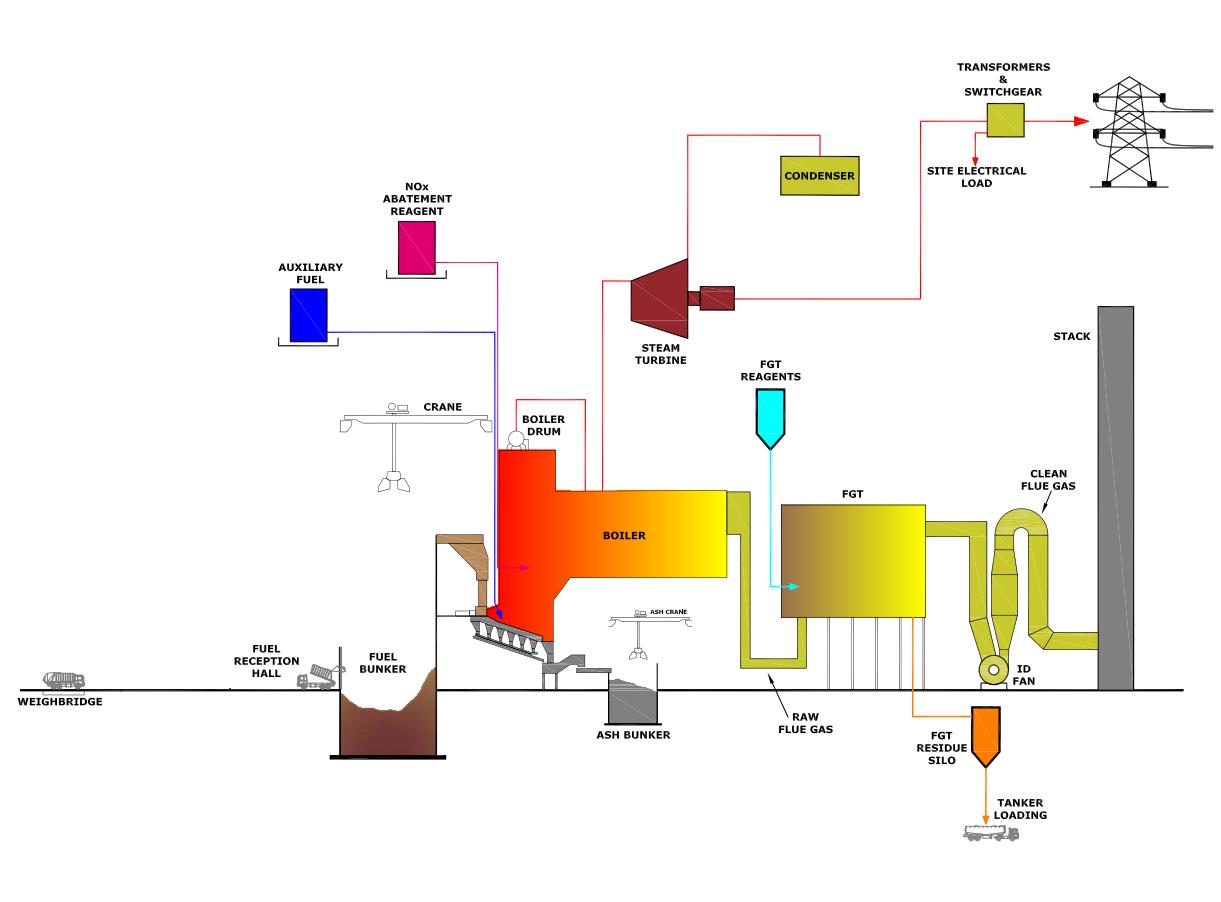

SHBEC will comprise a number of buildings and structures. The Main Building includes a fuel reception hall, fuel storage bunker, boiler hall, turbine hall, a flue gas treatment facility, and emissions stacks. Air-cooled condensers and an administration block would be situated nearby or adjoining the Main Building. There will also be vehicle weighbridges, internal access roads, ramps, parking, tanks and silos, a heavy goods vehicle (HGV) holding area and an electrical substation.

SHBEC will operate 24 hours per day, seven days per week with occasional shutdown periods for planned maintenance work. The fuel source for SHBEC will be ‘Refuse Derived Fuel’ (RDF). RDF is residual waste that has been processed to comply with the particular specifications of the end user regarding calorific value, moisture content, quantity and format. All RDF is likely to be delivered to the Site by road, using HGVs, via a new access road created from South Marsh Road. SHBEC will make use of up to 753,500 tonnes of RDF per year to produce enough electricity to supply the needs of close to 100,000 homes.

RDF will be combusted within SHBEC at temperatures above 850°C. The heat created will be used to produce steam, which can then be used to generate electricity using a steam turbine. Some of the steam could potentially be used to provide heat to local users. Any non-combustible material, such as glass, metal or stone, will be collected at the end of the combustion process and sent off site for reuse and recycling where possible.

Emissions from SHBEC will be cleaned by a sophisticated flue gas treatment facility before being released into the atmosphere. Emissions will be carefully controlled and monitored to ensure that they meet the stringent limits set by the Environment Agency and relevant legislation.

The proposed layout of the EfW Power Station and a process diagram are provided below.

Why was another application submitted for SHBEC?

After Planning Permission was granted for the Consented Development in April 2019, EPWM began assessing potential opportunities to improve SHBEC’s efficiency. It was subsequentley proposed that SHBEC would have a gross electrical output of up to 95 MW. In order to achieve this, the following works (additional to those which have been approved by the Planning Permission) would be required:

- Extended air-cooled condenser – an additional row of fans and heat exchangers will be added to the air-cooled condenser.

- Increased cooling capacity for the generator – to allow the generator to operate at an increased load and generate more power.

- Increased transformer capacity – to allow the generator to achieve up to 95 MW.

- Ancillary works – the above works will require ancillary works and operations, such as new cabling or pipes.

It is important to note that EPWM is not seeking any changes to the maximum building dimensions or fuel throughput that were approved by the April 2019 Planning Permission and assessed as part of the Environmental Impact Assessment that accompanied the planning application submitted to NELC. This is because of the conservative assumptions used in the assessment of impacts from the Consented Development.

As the Proposed Development would have a gross electrical output of more than 50 MW, it is classed as a ‘nationally significant infrastructure project’ (NSIP) under the Planning Act 2008. This means that it requires development consent from the Secretary of State (SoS) for Business, Energy and Industrial Strategy (BEIS) before it can be constructed and operated. The application process is administered by the Planning Inspectorate.

Why is SHBEC needed?

The UK needs to develop new low carbon electricity generation capacity to replace its ageing coal-fired and nuclear power stations, which are in the process of closing down and being decommissioned. There is also a need for alternative forms of generation that can provide a back-up for when intermittent renewable generation is limited by weather conditions (such as during low wind speeds or lower levels of solar energy). This is important to ensure that UK homes and businesses benefit from secure and reliable electricity supplies. The need for new electricity generation capacity, such as that which will be provided by SHBEC, is set out in government policy – the Overarching National Policy Statement for Energy (‘EN-1’) and the National Policy Statement for Renewable Energy (‘EN-3’). These documents can be found here.

SHBEC will also make a positive contribution to waste management by making use of waste material that would otherwise go to landfill or be exported overseas. The North East Lincolnshire Local Plan (2018) identifies that there is a need to ensure that there are sufficient waste management facilities within the Borough to meet the requirements of the area. Within the Local Plan the justification for Policy 49 ‘restoration and aftercare (waste)’ identifies that waste disposal through means such as landfill is the least desirable waste management option available.

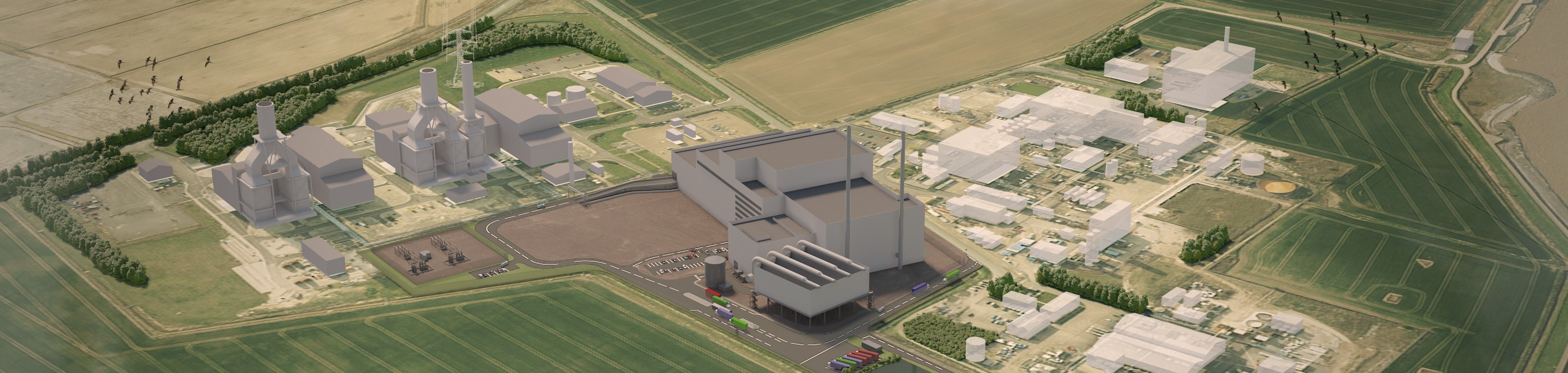

What could the EfW Power Station look like?

Below is a visual representation of what the SHBEC could look like. The detailed design of the EfW power station, including the types of materials used, will require the approval of NELC.

Environmental Impact Assessment

An Environmental Impact Assessment (‘EIA’) has been undertaken to consider the likely effects of construction, operation and eventual decommissioning of the Consented Development, as part of the planning application process. This EIA has informed the development of impact avoidance and mitigation measures, which have been incorporated into the SHBEC design, including:

- air emissions during operation will be carefully controlled through an Environmental Permit regulated by the Environment Agency and the stack height will be set at 100 m to disperse emissions effectively;

- piling will be controlled during construction to avoid disturbance of water birds using adjacent fields for roosting during winter;

- species-rich grassland will be created within the Site; and

- traffic management plans will be implemented during construction and operation, including designated HGV routes.

A revised EIA has been undertaken for the Proposed Development. This includes an assessment of the effects of the Proposed Development compared to no development at the Site, and also a comparison of the effects of the Proposed Development against the Consented Development.

The EIA for the Proposed Development includes the topics in the Consented Development EIA and takes account of the EIA Scoping Opinion issued by the Planning Inspectorate.

The EIA scope includes assessment of effects on air quality, noise and vibration, traffic and transport, ecology, landscape and visual amenity, geology, hydrogeology and land contamination, cultural heritage, water resources, flood risk and drainage, socio-economics, waste management, health, and sustainability.

The EIA also includes an assessment of cumulative effects with other developments that are proposed in the local area, such as cumulative air quality and transport effects.

Construction

It is anticipated that construction of SHBEC (up to 49.9 MW gross electrical output, pursuant to the Planning Permission) will commence as early as 2022. The construction phase is expected to last for approximately 36 months, with the EfW power station entering operation in 2025.

The impacts of the construction phase will be carefully managed through a Construction Environmental Management Plan. This will include management measures relating to the storage of materials, surface water runoff/drainage, construction traffic and working hours and also measures to ensure a clean and safe working environment.